Installing an Overdrive T5 Transmission in a Model A Ford

Five Forward Gears for a Model A

By Ryan Manson * clampdowncomp@gmail.com

A Model A Ford can be one of the simplest machines in which to work. That’s a good thing becuase if you own one, chances are there’s something that needs to be worked on. When I purchased my ’30 coupe, there was a laundry list of small things that needed to be done and an even larger list of things I wanted done. I tackled that small laundry list first with things like rebuilding the water pump, carb, and updating the ignition and electrical to 12volts. These were things that were necessary; the water pump and carb leaked, while the wiring harness was held together with residential wire nuts. Back on the road, it became painfully obvious by the ever increasing noise emitted from the transmission that it would require my attention next. That’s when I had to make a drastic decision; rebuild the existing transmission or upgrade the stock 3-speed with a T5.

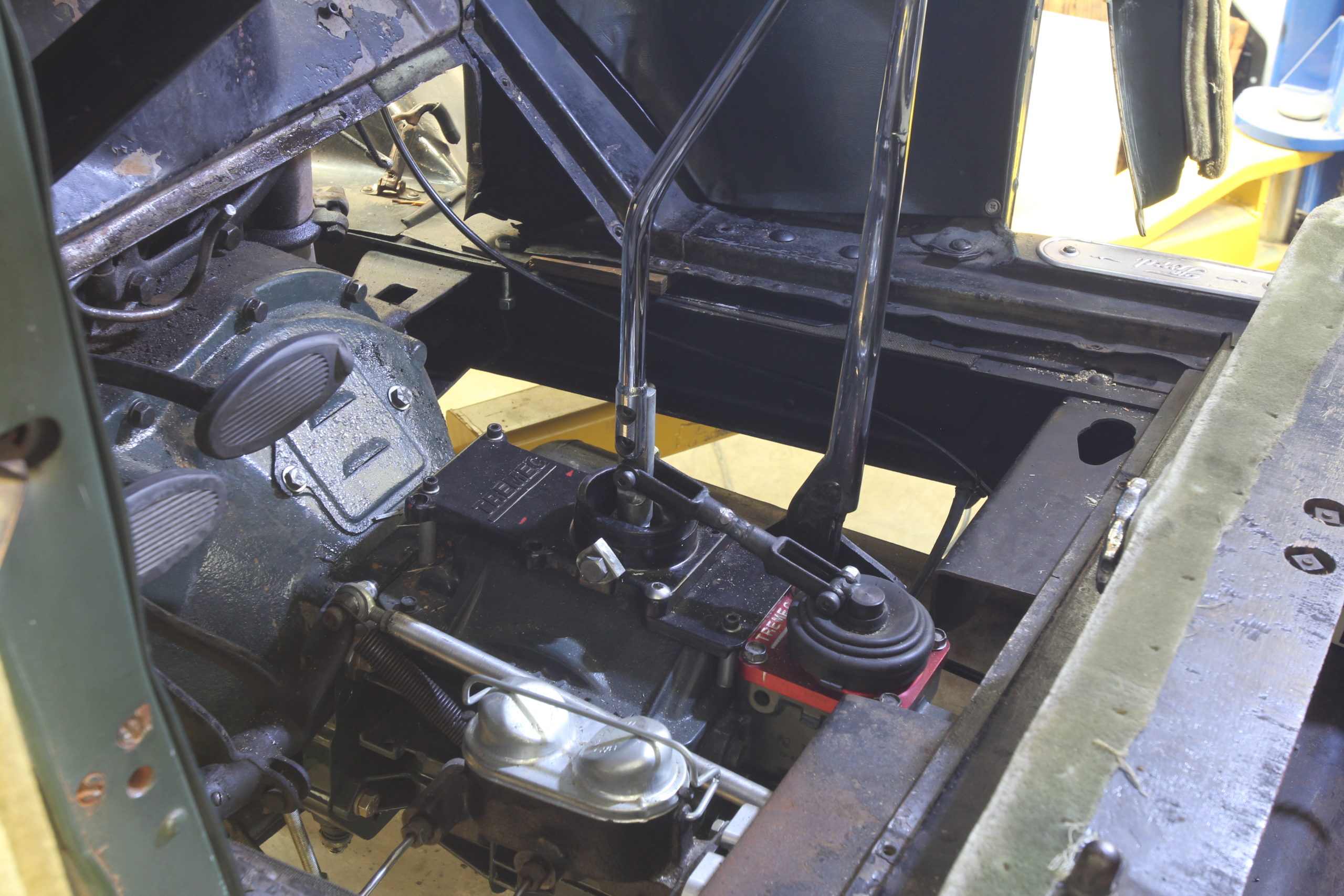

If I’m honest, by the time I was ready to pull the transmission, I had already decided the coupe could use not only a couple more gears, which meant I could now make a slightly safer attempt at highway driving, I was also done with the double clutching, no syncro-shifting driving that occurred using the original transmission. The fact that I had a good T5 with an S10 tailshaft sitting under my work bench made the decision even easier.

There have been a handful of T5 kits available on the aftermarket, but they all seem to lack one thing or another. Some use the stock Model A bellhousing (so as to keep the pedal mount) with an adapter, but that can push the trans too far rearward. Others use a custom bellhousing designed to replace the Model A unit, with the T5 bolt pattern machined in place. Some were fairly inexpensive while others were outwardly the opposite. Most were out of business or unavailable. Unsure on how to proceed, it was while surfing the ‘net one night looking for a solution that I came upon the website for Vintage Metalworks. I jotted down the phone number and gave Dave Farwell a call that following morning. Turns out they not only had a kit to do the swap, but also offered a couple other solutions I hadn’t thought of.

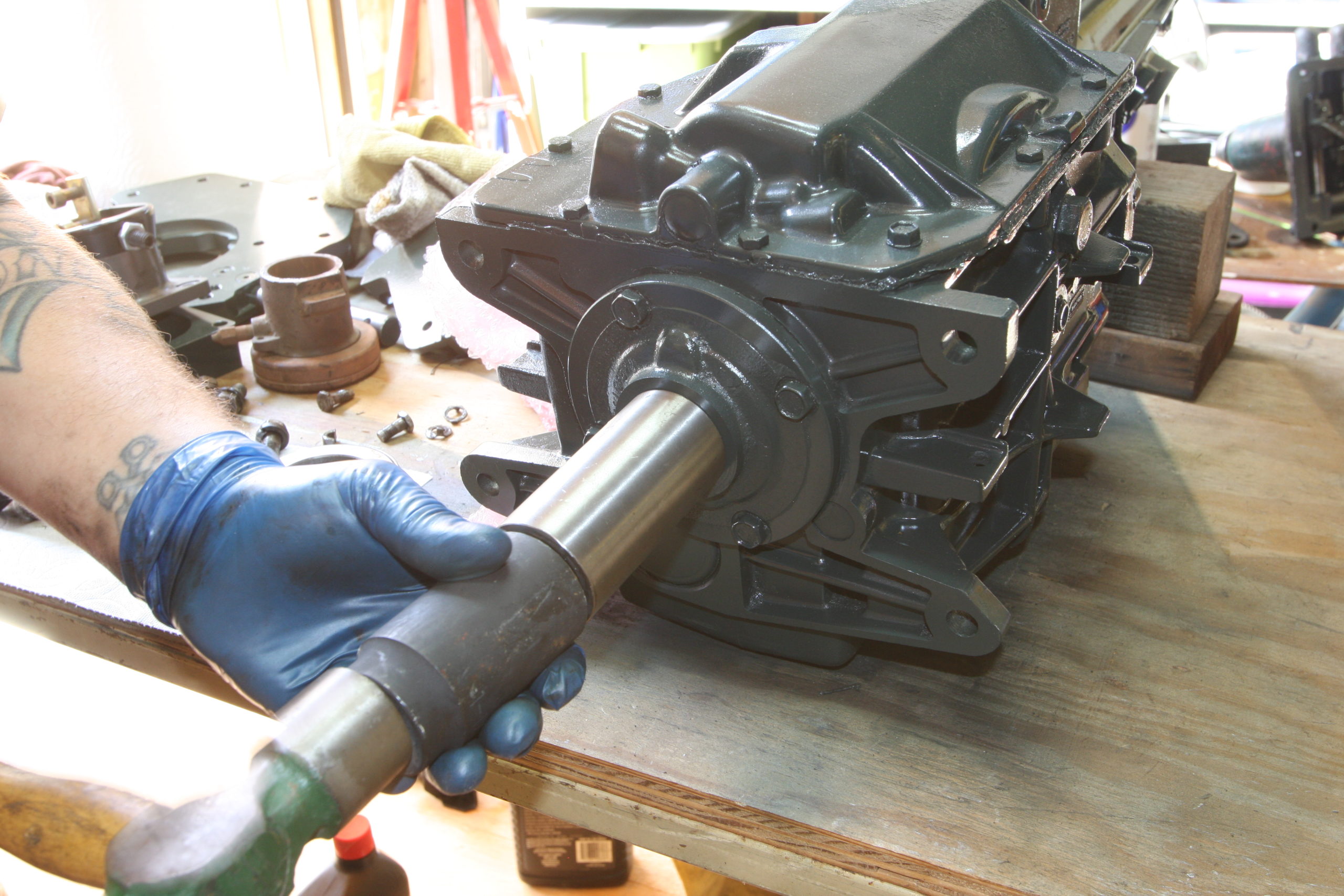

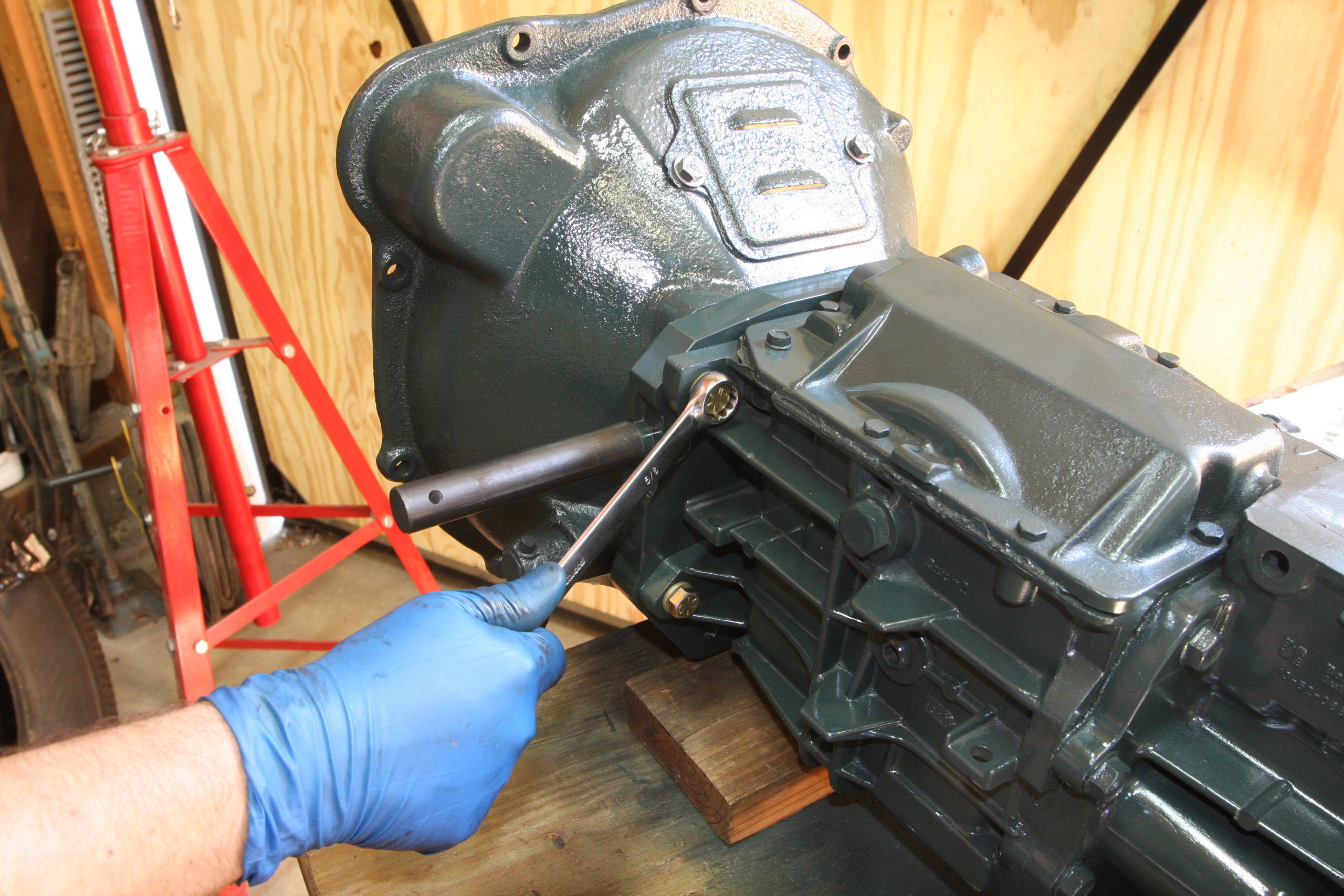

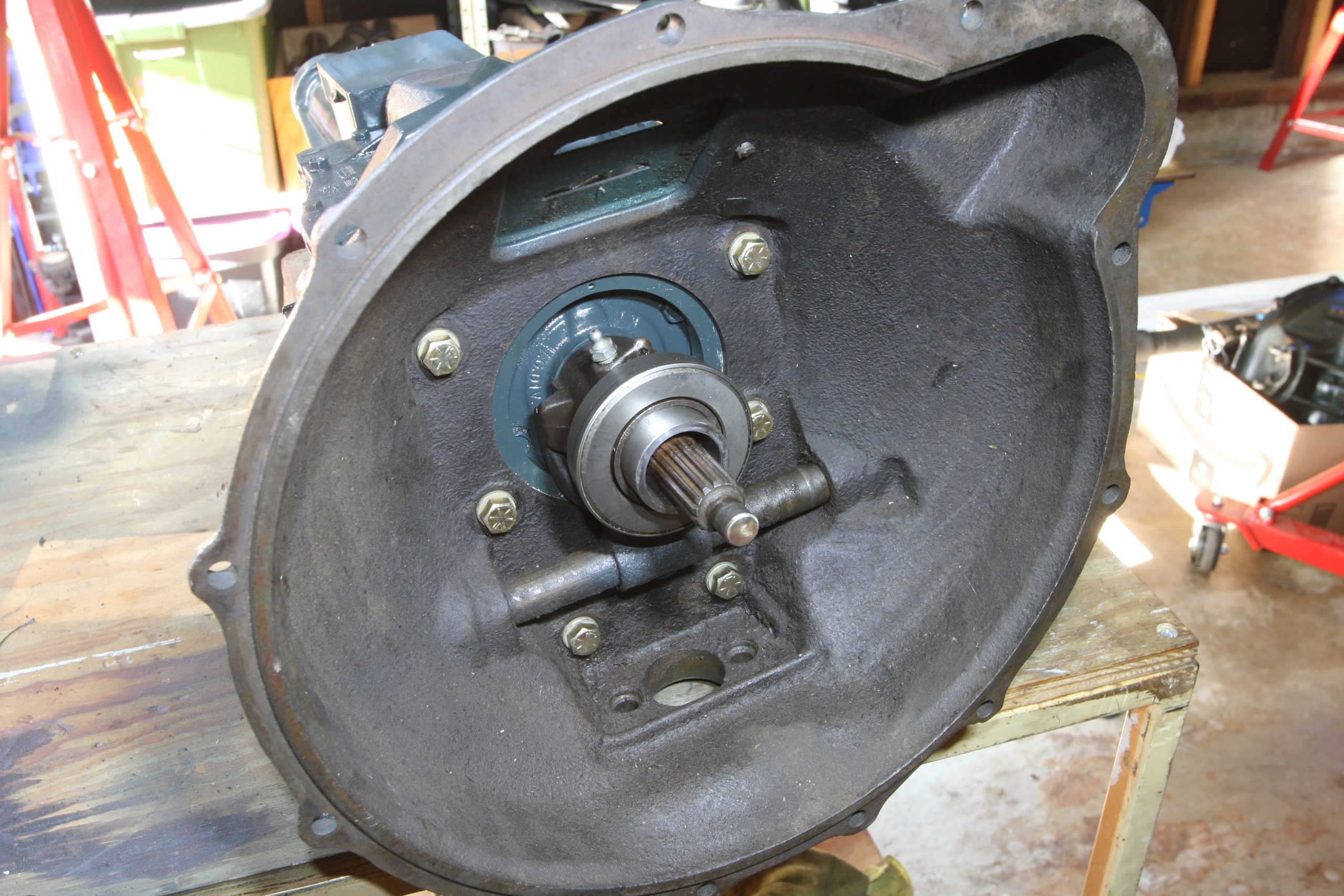

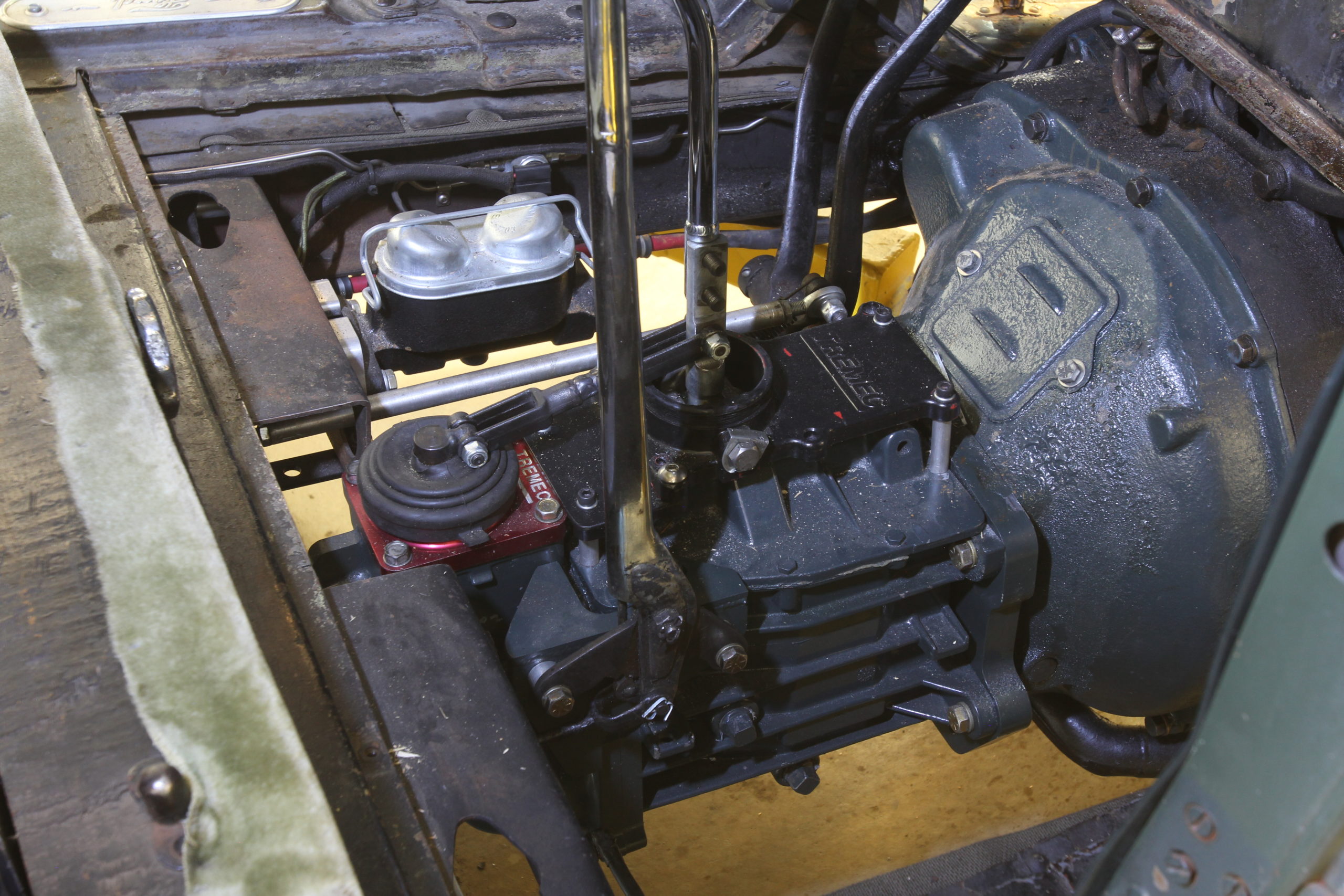

Vintage Metalworks’ kit is designed to be used with a Ford AA bellhousing, found on the larger trucks of the same era (’28-32). The AA bellhousing is 2 1/2-inches shorter than the stock Model A bellhousing, which means three things; the input shaft on the T5 doesn’t need to be extended, the shifter (with an S10 tailshaft) is in front of the bench seat, and there is less conflict with the center crossmember. The AA bellhousing retains the same location for the front wishbone mount as the Model A, so that remains uneffected. The only problem with using the AA bellhousing is that the original unit had an integrated pedal shaft and the AA does not. That required some careful thinking by Dave, but he came up with a clever design by mounting the pedal shaft on the same adapter plate that mates the T5 to the AA bellhousing; problem solved! As it turns out, this locates the pedals in the stock location, so further modifications are unnecessary. This takes care of mounting the transmission, but there are a few other components required to make everything work. For those ends, Vintage Metalworks offers a clutch that’s designed to fit the diameter/spline of the T5’s output shaft and fits the stock Model A pressure plate. A collar adapter is also provided that slides over the T5 output shaft so that the original throwout bearing can also be used. A pilot bearing that supports the T5’s input shaft inside the Model A flywheel is the last item in the kit.

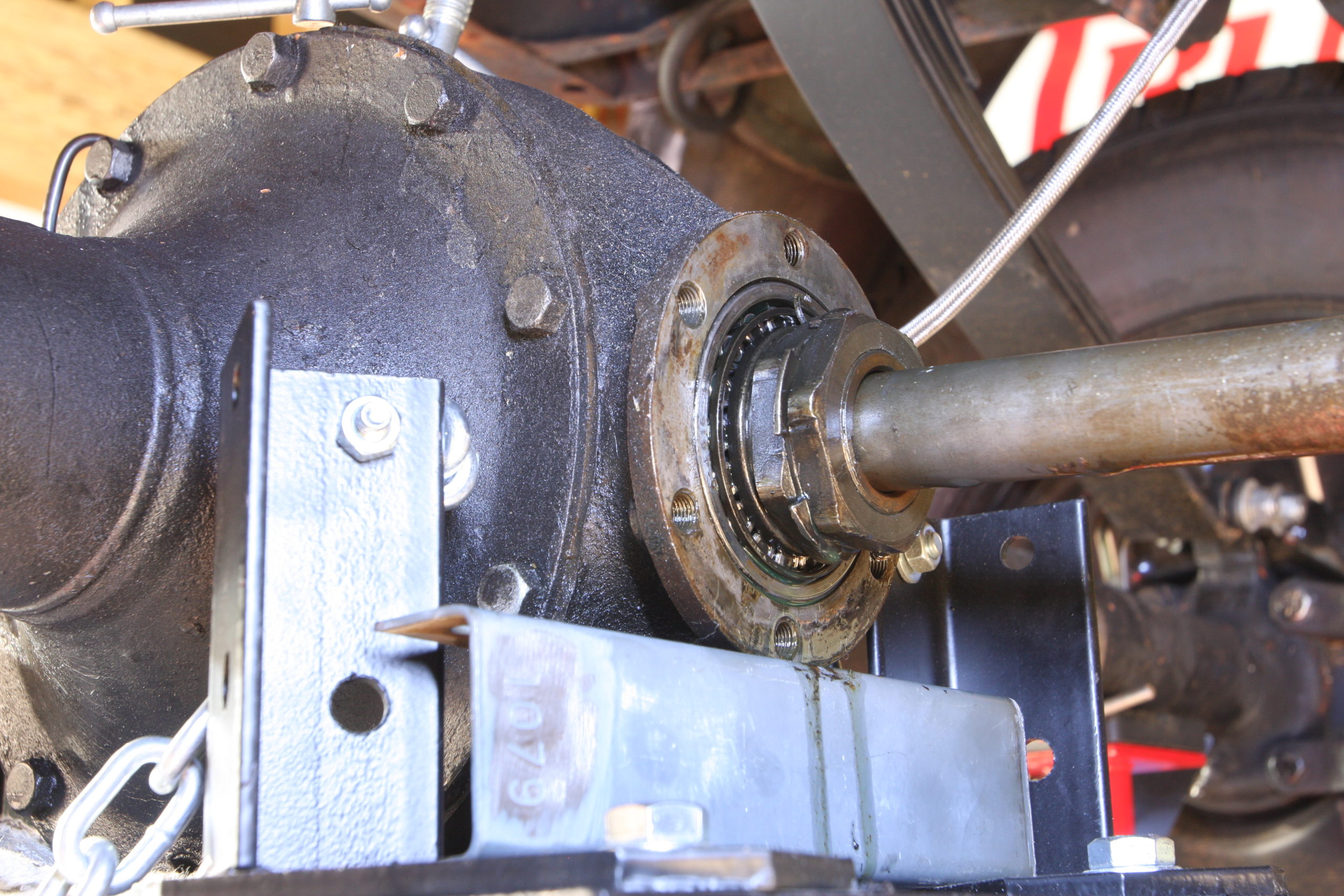

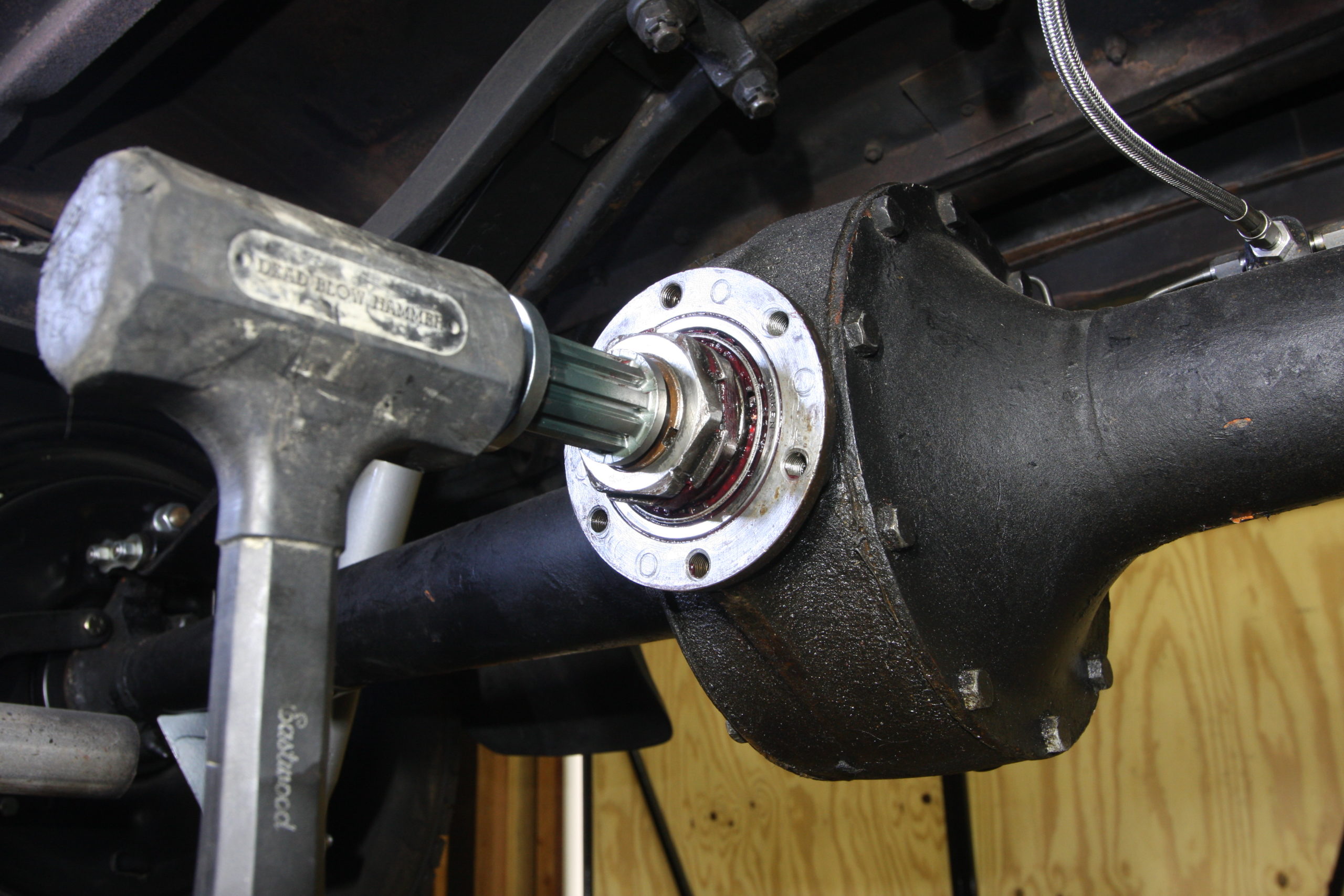

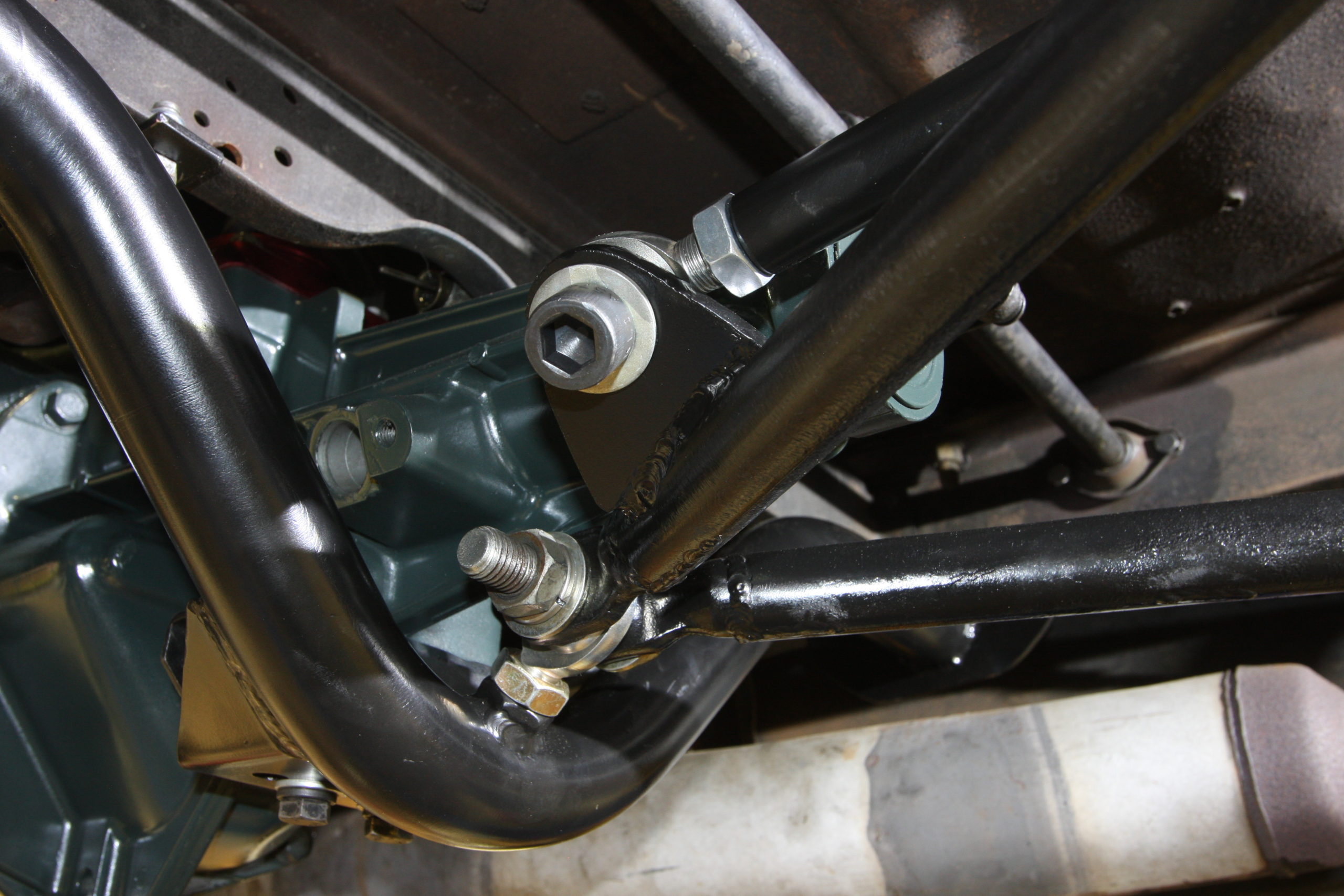

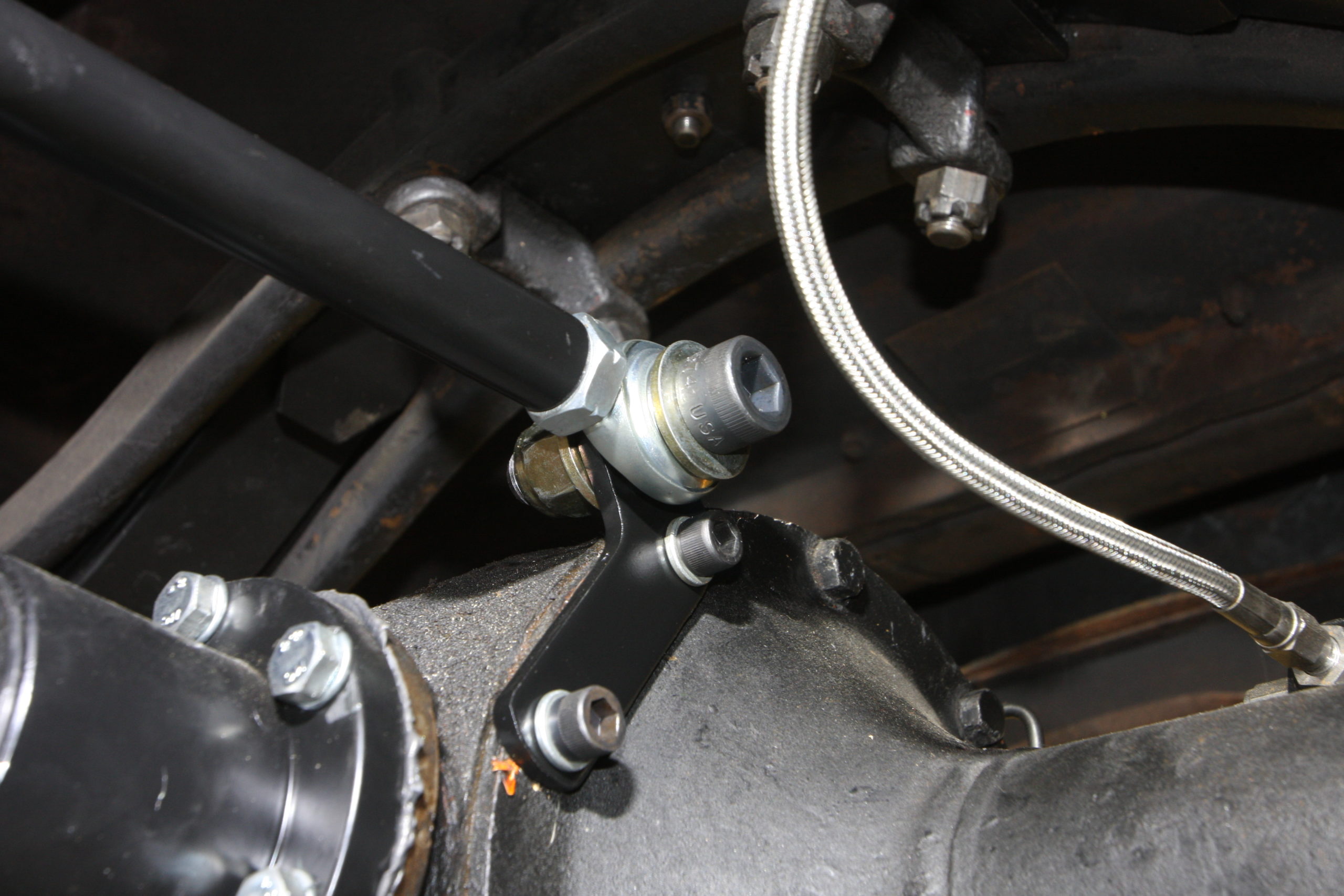

While installing Vintage Metalworks’ T5 kit was straight forward, there were a few side effects that came with fitting a larger transmission into a Model A that weren’t so simple. For starters, installing the T5 meant changing over to an open driveline. Simple enough since Speedway Motors has a kit made specifically for the Model A. But Ford refers to the driveshaft housing as the “torque tube” for a reason, as it controls the rearend’s tendency to wrap during braking or accelerating. Those spindly, pressed rear wishbones won’t handle any kind of torque, so something will need to be done to counter that force now that the torque tube is gone. And regarding that torque tube, the rear wishbones mounted to it, so a new mount is also required. The shifter on the T5, even with the forward mounting position of the S10 tailshaft, pops up through the floor about 8-inches to the rear than stock. The parking brake handle originally mounted off the transmission so this will need to be relocated as well. Thankfully, Vintage Metalworks offers a bracket that mounts the parking brake handle off the T5 trans. The problem with this is that, like the shifter, the location is different from stock due to the T5’s larger dimensions. While these are conflicts that can definetely be dealt with, they’re worth mention since the stock floorboards will need to modified (easy) as will the carpet or floor mat (not so easy). We’ll show you how we tackled these issues and you can formulate your own opinion, but for now, let’s see what it takes to add a gear or two to a Model A. CC

| Sources: | |

|---|---|

| Classtique Upholstery (651) 484-9022 www.classtiqueupholstery.com | Harbor Freight (800) 444-3353 www.harborfreight.com |

| Inland Empire Driveline Service (800) 800-0109 www.iedls.com | Lokar Performance Products (877) 469-7440 www.lokar.com |

| Speedway Motors (800) 979-0122 www.speedwaymotors.com | Vintage Metalworks (330) 322-3102 www.vintagemetalworks.blogspot.com |