Adding a vintage oil fill tube to a modern intake

We machine our new Edlebrock intake to accept an oil fill tube and look the vintage part!

Back before PCV valves were standard lexicon among hot rodders, venting a motor was oftentimes a simple matter of letting the crankcase vent to the atmosphere via either a road draft tube or a breather apparatus of some sort. When it became passé to dump raw hydrocarbons into the atmosphere, more exotic methods were adopted. If you’re building an engine that yearns to identify with a certain era’s aesthetic, like the 383 that we’re building, then simple things like crankcase ventilation and oil fill start to become important build aspects.

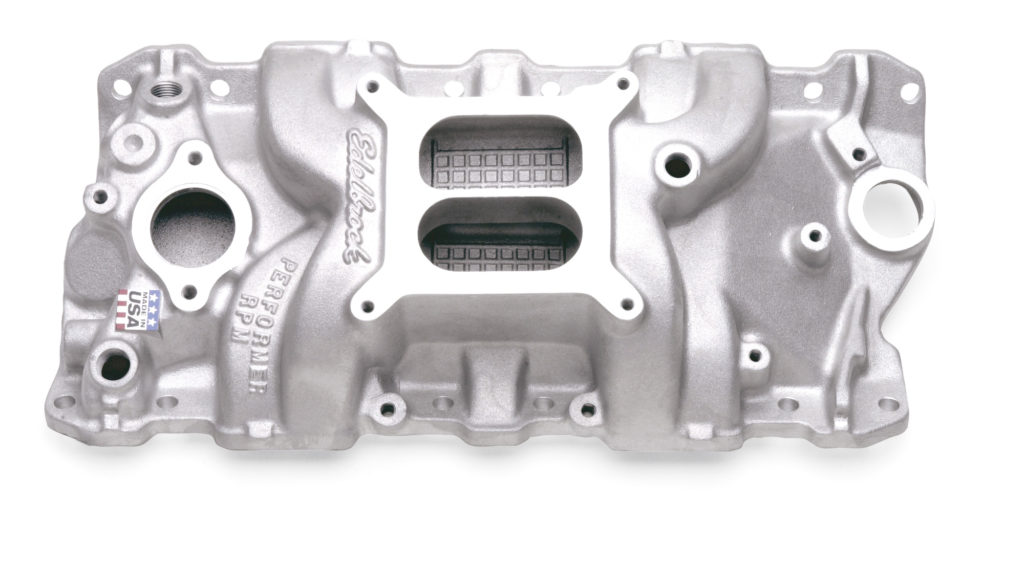

And what better way to achieve said aesthetic than to incorporate an oil fill tube to a modern intake manifold? To get the fuel into our motor, we’re going to use an Edelbrock Performer RPM intake manifold. While outwardly similar in appearance to an original four barrel manifold from a 283, it features a port design that is 100% 21st century technology, providing power like a single-plane and throttle response like a dual-plane. Couple that with the ability to add an oil fill tube for that vintage look and you’ve got the best of both worlds.

Unfortunately, if you want to add an oil fill tube to your Edelbrock manifold, you’re going to have to approach your local machine shop with a 6-pack and a smile as Edelbrock doesn’t offer it “out the door”. They do however offer everything it takes to make a modern intake look the part on a vintage motor, which is worth its weight in salt.

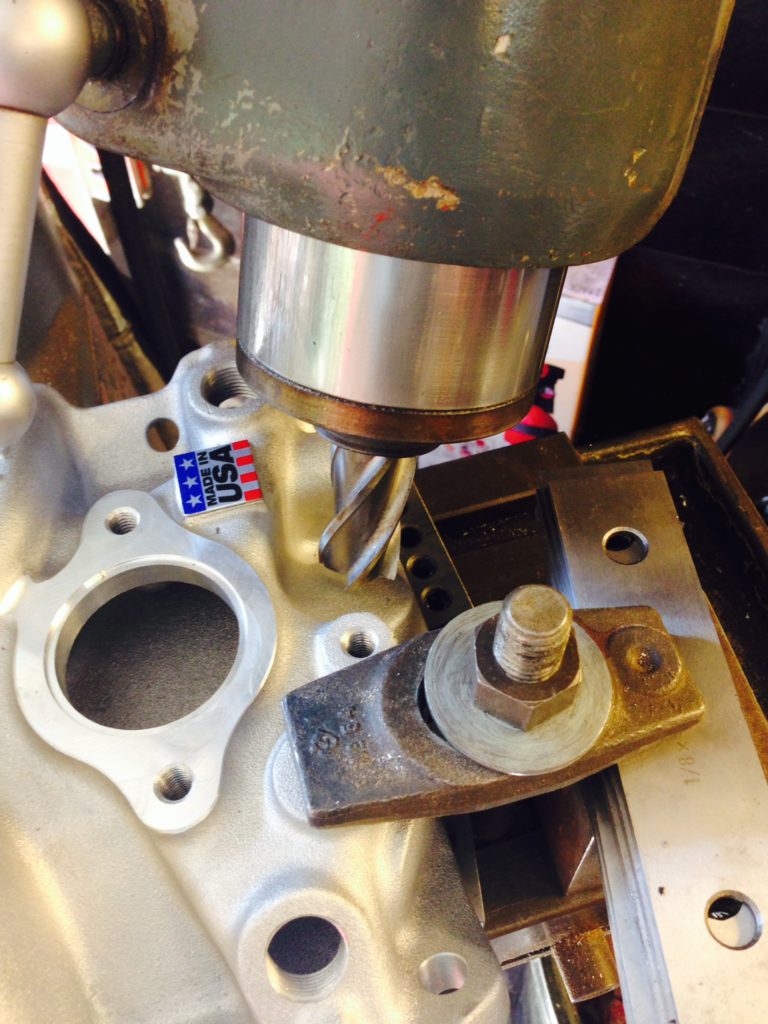

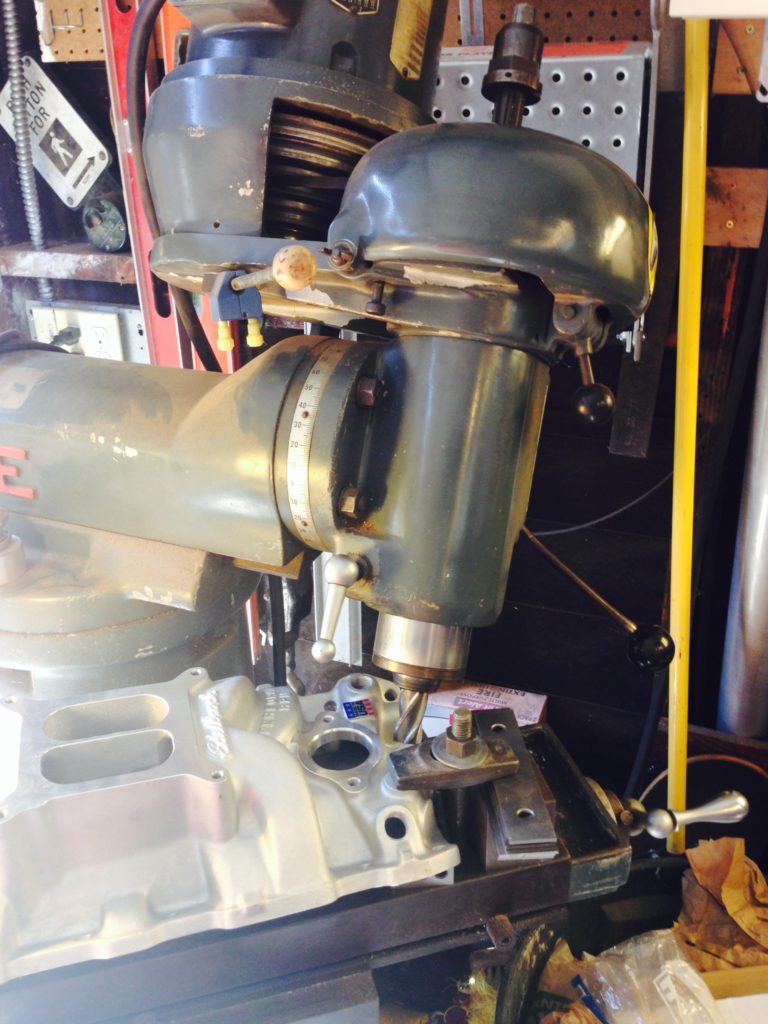

For our 383 build, Edelbrock sent us everything we needed, intake, tube, and breather cap, and we did the rest thanks to our trusty Millrite milling machine. There’s just no substitute for the right tools is there?! CC

| Sources: | |

|---|---|

| Edelbrock (310) 781-2222 www.edelbrock.com | Eastwood (800) 343-9353 www.eastwood.com |