Dressing up a modern engine with vintage amenities

383 SBC Build, Part IV

By Ryan Manson * clampdowncomp@gmail.com

It’s pretty exciting when your engine project starts coming together and you’ve finally got an assembled long block on your engine stand. For me, it’s usually the culmination of months of planning and a few evening’s worth of assembly. This is also the point where anxiety can really start to set in, especially if your plan (like ours) involves expensive dyno testing at the end. A big boom in the dyno cell means not only a day’s session down the drain, but a definite hit in the pocketbook when it comes to repairing that damaged mill. And if you’ve ever goofed something like an engine build up, you know how stressful it can be to get back in the saddle the second time. But you can’t let the fear of the possible results keep you from trying new things.

With our engine assembled and our dyno session scheduled, it’s time to turn our attention to the ignition, induction, and component selection. As we’ve alluded in past stories, our final setup will include a TorqStorm centrifugal supercharger, which we’ll cover in full in part five. This will be blowing through an MSD Atomic EFI throttle body setup atop the aforementioned Edelbrock Performer RPM intake manifold. We chose to use the MSD Atomic setup for a number of reasons, including packaging and compatibility. As mentioned before, one of our goals with our 383 engine was to build an engine that looked like it came from the early ‘60s while benefiting from a number of hidden, modern performance pieces. One of these items is the MSD Atomic system.

The MSD Atomic throttle body is unique in that the ECU is an integral part of the throttle body as are the 2-Bar MAP, TPS, IAT, and fuel pressure sensors. This translates into a less bulky package, with only a handful of wires exiting the rear of the throttle body, and only two external sensors to connect, coolant temp and O2. Essentially, with the exception of a few wires that will need to be run down the backside of the intake, the Atomic EFI throttle body is similar in installation to that of a standard square bore carburetor, with passenger side fuel fittings and identical linkage. Four 80lb/hr fuel injectors work in conjunction with the annular rings cast into the throttle body, good for over 600 horsepower. In addition to the throttle body, MSD’s Atomic EFI system consists of a Power Module that acts as the communication hub and provides the high current fuel pump circuit and other input/outputs for optional features as well as a Handheld Monitor, which serves to input information to the ECU regarding certain engine parameters. All of the programming is performed via the Handheld Monitor, negating the needs to connect an external laptop. The Monitor connects directly to the Power Module and can be removed following initial setup and engine operation.

One of the neat features of the MSD Atomic system is its ability to not only control fuel but also timing. This is achieved in conjunction with an MSD 6A or similar ignition control box and a locked-out distributor. Settings for idle timing, total advance, and vacuum advance are available through the Handheld Monitor. The Atomic EFI system requires an rpm/trigger reference signal to operate, which can be triggered when connected to coil negative on breaker points, GM HEI, or Ford TFI inductive based ignition systems. We opted to take control of the ignition system even further while also satisfying this need by using an MSD Pro-Billet distributor. This CNC machined dizzy contains a precision machined reluctor attached to the distributor’s shaft which triggers the magnetic pick-up mounted in the housing, making it one of the most accurate ways to trigger the ignition. With no moving parts to wear or adjust, our distributor truly is “set it and forget it”.

To feed the fire, we’ll be using an Aeromotive Stealth in-tank fuel pump plumbed in the traditional return-style with an Aeromotive EFI regulator on the return side of the system to ensure proper fuel pressure at the injectors.

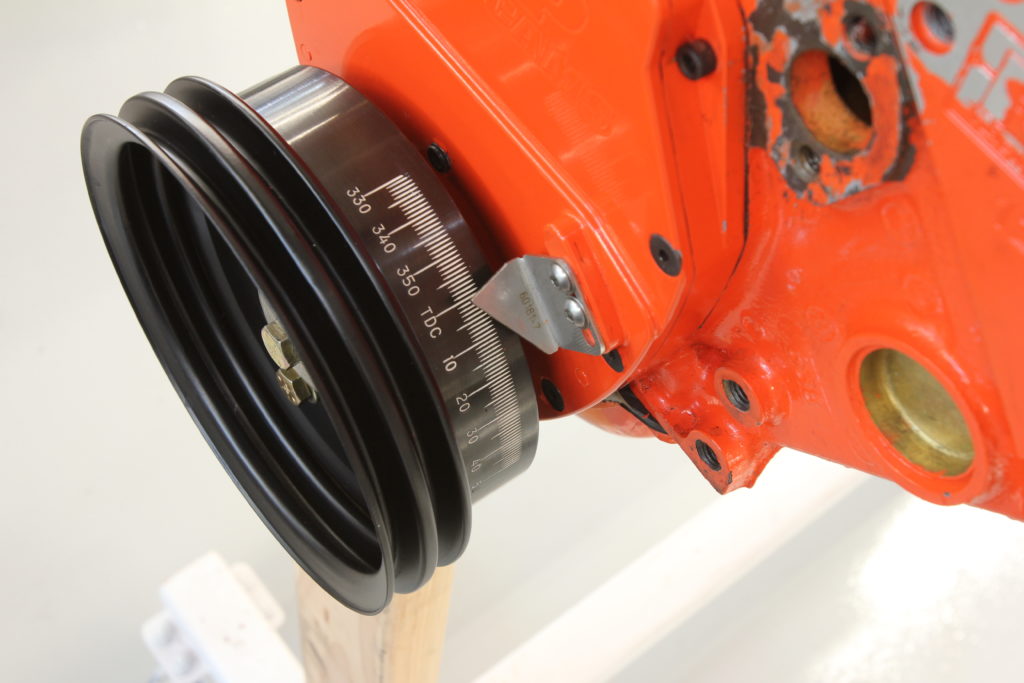

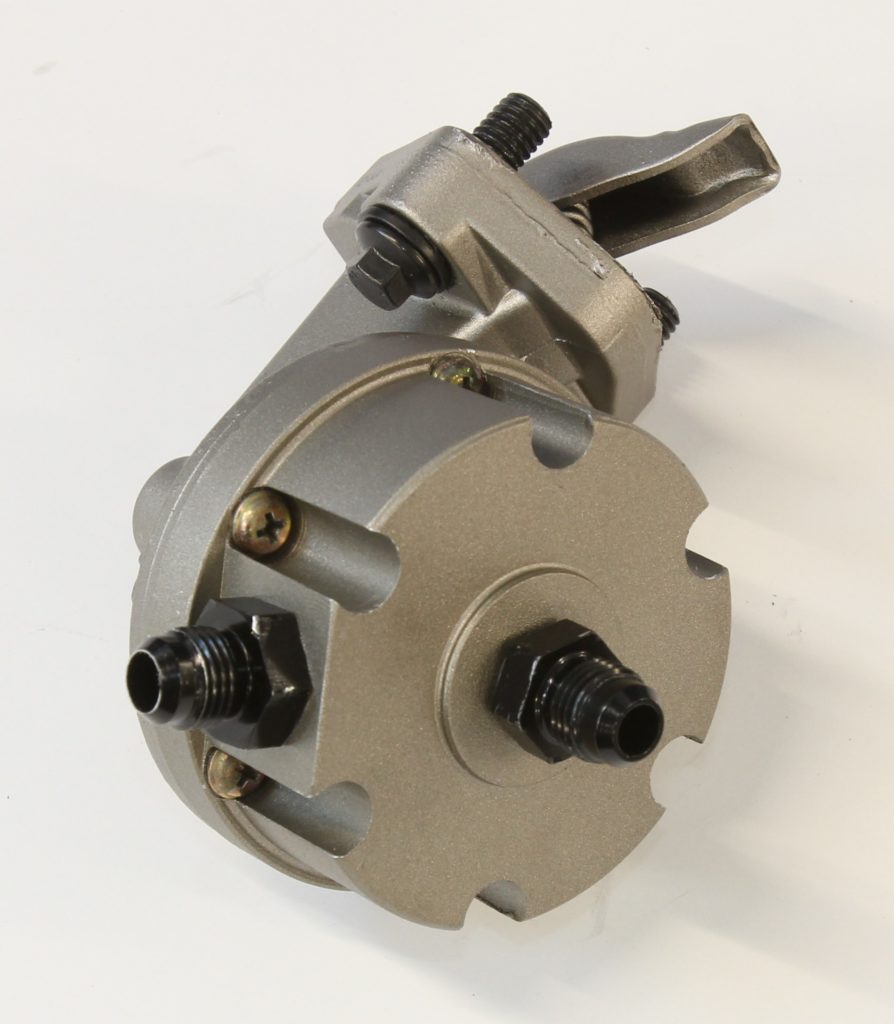

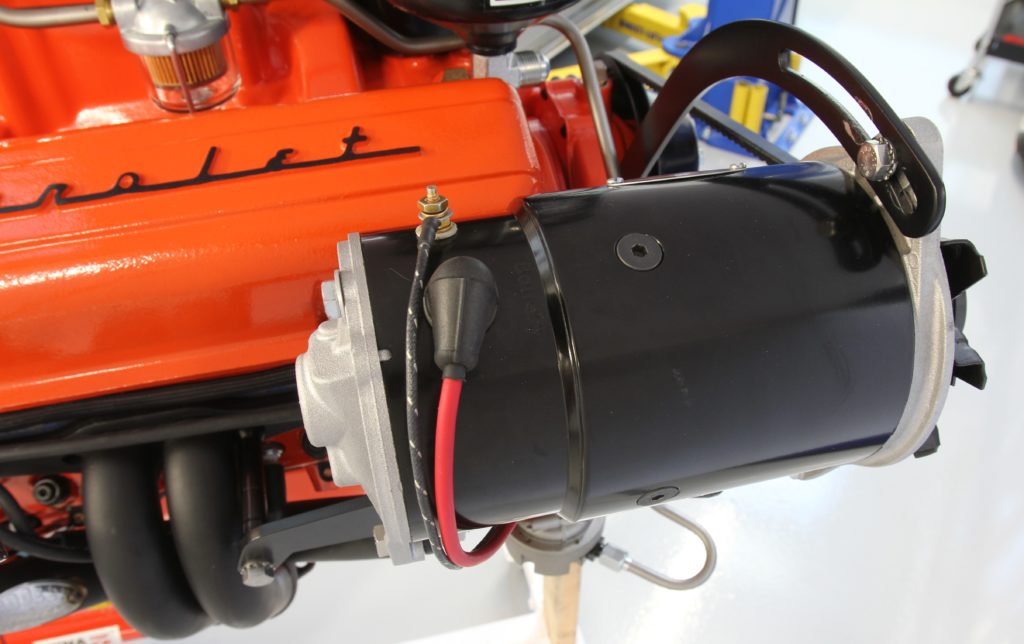

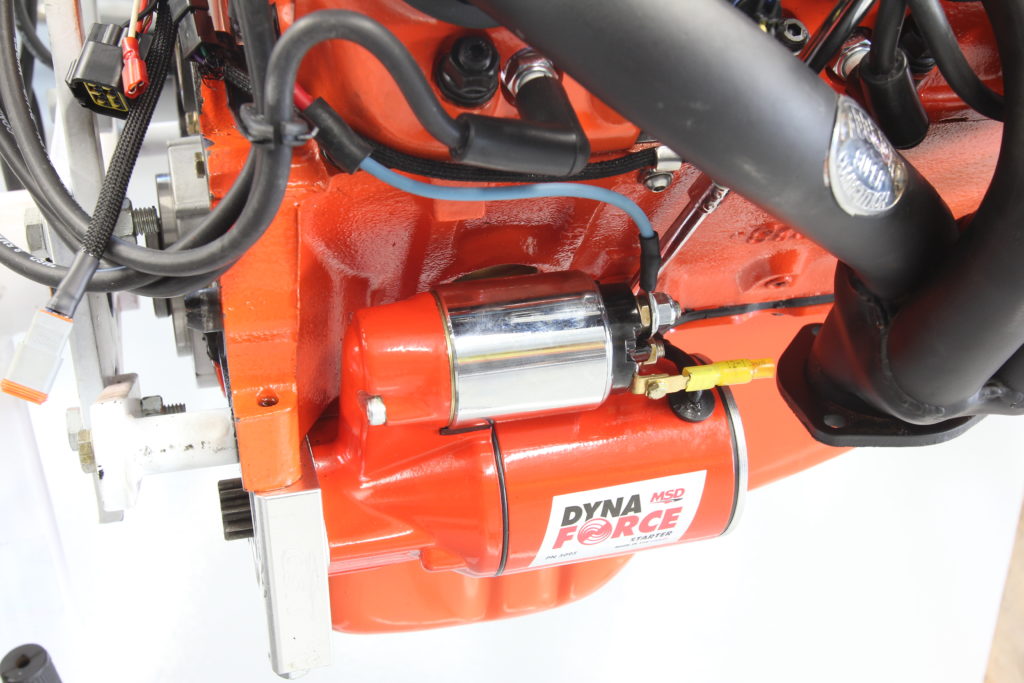

In addition to the components that will control the fuel and spark on our motor, we also need to choose and mount a couple accessories. For that end and to further enhance the vintage appeal of our “283 in disguise”, we opted to use a Powermaster PowerGEN alternator. Disguised as a vintage generator, the PowerGen unit contains the same modern internal components as its contemporary alternator brethren, capable of providing a total output of 90 amps, with a whopping 60 amps at idle. The other accessory that we’ll need to install is a power steering pump. Our initial idea was to use an early ‘60s-style Saginaw pump with an integral reservoir. Unfortunately, space constraints as well as belt and pulley alignment issues forced us to shift gears and look for an alternative. Since the TorqStorm supercharger system was designed to utilize a two-groove v-belt pulley, we needed a power steering pump that was compact enough to fit behind the blower’s bracketry while still maintaining proper pulley alignment. A quick perusal through Tuff Stuff’s website yielded a later-style Type-II power steering pump that would fit perfectly, though it will require the use of a remote reservoir (more on this a little later). To mount our accessories, an off-the-shelf power steering bracket from Alan Grove Components will be used to mount the Type-II pump while an alternator bracket, also provided by Alan Grove Components, will be modified to mount the PowerGEN. Driving our accessories will be accomplished via Trans Dapt double-groove pulleys on the crank and Weiand water pump. Wrapping up the accessories are a Weiand Action +Plus water pump and MSD DynaForce starter.

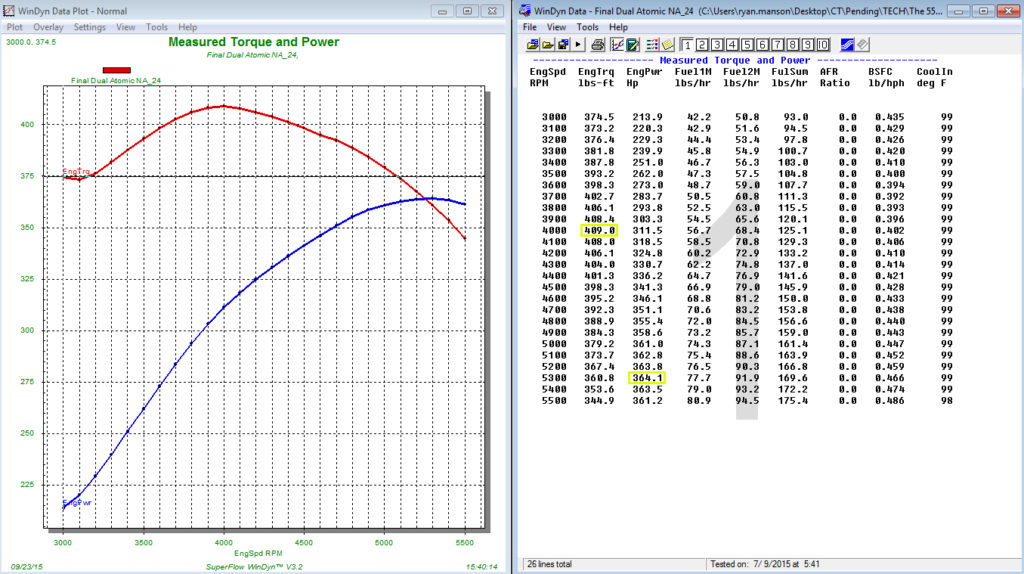

Once our accessories were sorted and the necessary components installed, it was time to load our 383 into the back of our work truck and head out to Mira Loma, California where Steve Brule and the crew at Westech Performance were ready for our test and tune day on their engine dyno. After filling the motor with Comp Cams Break-In Oil and following their break-in procedures, Steve progressively brought our engine up to operating temperature. After a few initial base pulls, the MSD Atomic EFI system had enough operating parameters to allow us to set down a decent set of dyno numbers; 409 lb. ft. torque / 364 horsepower. While not that impressive outright, keep in mind our 383 was built and designed with boost in mind, so these results are typical of a low compression engine. When it comes time to put some boost into our motor, we should see both of those numbers creep up at least another 100 points. Then we’ll really have something! CC

| Sources: | |

|---|---|

| Aeromotive, Inc. (913) 647-7300 www.aeromotiveinc.com | Alan Grove Components (913) 837-4368 www.alangrovecomponents.com |

| Automotive Racing Products, Inc (ARP) (800) 826-3045 www.arp-bolts.com | Classic Industries (800) 854-1280 www.classicindustries.com |

| Comp Cams (800) 999-0853 www.compcams.com | Eastwood (800) 343-9353 www.eastwood.com |

| Edelbrock (310) 781-2222 www.edelbrock.com | Fel-Pro www.felpro-only.com |

| Holley (866) 464-6553 www.holley.com | Hooker Headers (866) 464-6553 www.holley.com |

| MSD (915) 855-7123 www.msdperformance.com | PML (310) 671-4345 www.yourcovers.com |

| Powermaster Performance (630) 957-4019 www.powermastermotorsports.com | Racing Head Service (RHS) (877) 776-4323 www.racingheadservice.com |

| Summit Racing (800) 230-3030 www.summitracing.com | TCI Automotive (888) 776-9824 www.tciauto.com |

| TorqStorm (616) 706-5580 www.torqstorm.com | Trans Dapt Performance Products (562) 921-0404 www.tdperformance.com |

| Tuff Stuff (800) 331-6562 www.tuffstuffperformance.com | Weiand (866) 464-6553 www.holley.com |

| Westech Performance (951) 685-4767 www.westechperformance.com |